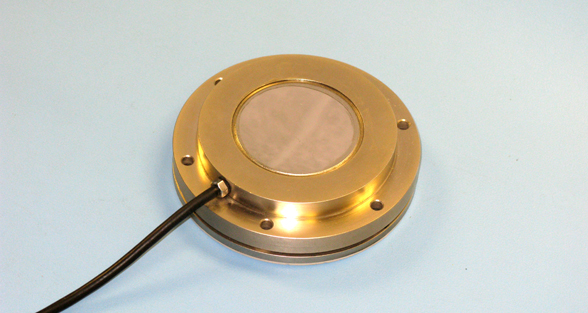

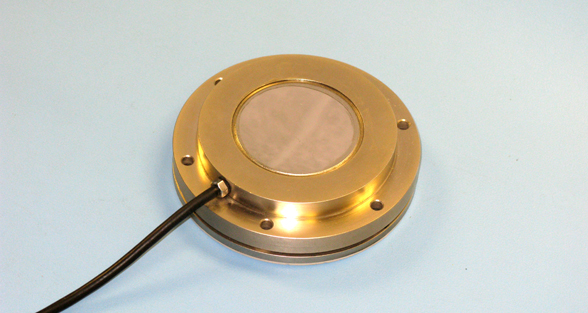

Weight disc

2,000 kg up to 10,000 kg

We work with you to optimise the design for your tank weighing

Immediate advice: +49 (0) 29 61 – 96 56 86

The added value to you

Compact

Options available

Simple

Approved for certification

Why is the weight disc the right choice for my plant?

With the benefit of our many years of experience we assist you in selecting the load cell suited to your application.

+49 (0) 29 61 – 96 56 86

You are probably familiar with the following situation:

You have one or more existing tanks in a hall.

The sensor for the level indicator is inaccurate and has to be cleaned regularly.

The optimum solution would be an external weight measurement device, but there is hardly any additional height to install load cells.

The expense and effort for shortening the container feet is too great.

The ideal solution:

The weight disc requires only 31 to 40 mm total height, while providing a measurement range from 2,000 to 10,000 kg/load point. It nearly always fits.

The disc slides under the feet like a beer mat and can be screwed together with the load.

The error of measurement (force shunt free) is only 0.02%.

The weight disc is very economically-priced and models approved for certification can be supplied.

Upon request, we will gladly send you a series of information about our products, starting with the access to our data sheets.

How does the weight disc work?

The weight disc works like a pressure load cell and offers a simple, cost-effective solution to weighing interior tanks.

Because of its low total height, the weight disc is ideally suited for retrofitting existing containers with maintenance-free inventory control based on weight.

Just like platform scales, the tank is simply placed on the weight discs.

Technical data

Measurement ranges:

2,000 kg, 5,000 kg and 10,000 kg

Total height:

31 – 40 mm

Supply:

5-12 VDC, max. 15 V

Output signal:

1.7 mV/V

Combined error:

0.3% of full scale output

Overload protection:

150% of the nominal load

Output resistance:

350 Ohm

Working temperature range:

-10°C to +70°C

Compensated Range:

-10°C to +45°C

Insulation resistance:

> 1,000 MOhm

Frequently asked questions

On how many load cells may a silo, vessel or container be placed?

There is no real limit to the number of load cells, apart from cost.

Since the load should be distributed as evenly as possible, 3 or 4 supports are easier to balance than 12.

Because of the parallel switching in analogue load cells, care must be taken that the measurement amplifier can supply the required number.

What is an anti-lift-off device?

Integral anti-lift-off device:

The anti-lift-off device prevents the silo or container from tilting. The Safemount and Baby-Safemount weighing assemblies, which are used for silo weighing, have integral anti-lift-off devices. The top and bottom mounting plates in the assembly are connected to the load cell by bolt connections. In this way, the assembly compensates a certain expansion (e.g. caused by different thermal coefficients between steel and foundation materials) of the overall structure and also limits the distance that can occur in the case of a lifting silo.

Additional anti-lift-off device:

An additional anti-derail device is frequently used for load cells which do not have integral anti-lift-off devices. In this system, the anti-lift-off device can be attached to the load cell itself or directly to the silo or container. When statically required for the Safemount weighing assembly up to 40 t, additional anti-lift-off device, which are attached directly to the weighing assembly, are available. In this version, two vertical threaded rods are screwed into the bottom mounting plate. Each of these protrudes through a drilled hole in the top mounting plate without touching the plate. The maximum withdrawal distance is limited by a nut above the top plate at 2 – 3 mm and additionally secured by a lock nut.

What are stay rods?

Windhoff