Weigh Beams

The flexible solution for industrial weighing…

We work with you to find a weighing system suited to your requirements

Place your request for a quotation now and we will be pleased to give you individual advice on your performance requirements.

Immediate advice: +49 (0) 29 61 – 96 56 86

The added value to you

Precise

Outstanding repeatability and accuracy

Multi-faceted

Various dimensions, materials and measuring ranges

Automated

From simple electronic display up to full automated weighing with bar code system

Plug & Play

Mobile use: plug in, switch on, weigh

Strong

One outstanding feature of our weigh beams is their sturdy design

Easy

Calibrated ex works

Upon request, we will gladly send you a series of information about our products, starting with the access to our data sheets.

Why is the weigh beam the right choice for my plant?

With the benefit of our many years of experience we help you to select the right equipment for your application.

Place your request for an offer now and we will be pleased to help you:

+49 (0) 29 61 – 96 56 86

You are probably familiar with the following situation:

You need a robust, high precision weighing system for mobile or stationary use.

The weighing system should offer a good price/performance ratio.

The electronics must meet your performance requirements and where required, offer a printer and/or process interfaces.

The ideal solution:

The low tare weight and the flexible layout of the weigh beams allows to weigh goods of almost any dimensions (approved weighing, where required).

The measuring ranges go from 0.5 kg up to 20,000 kg.

The evaluation electronics can be supplied in a variety of versions – as a simple weight display, remote displays or with article database and versatile interfaces (RF / Wi-Fi /Bluetooth).

How does the weigh beam work?

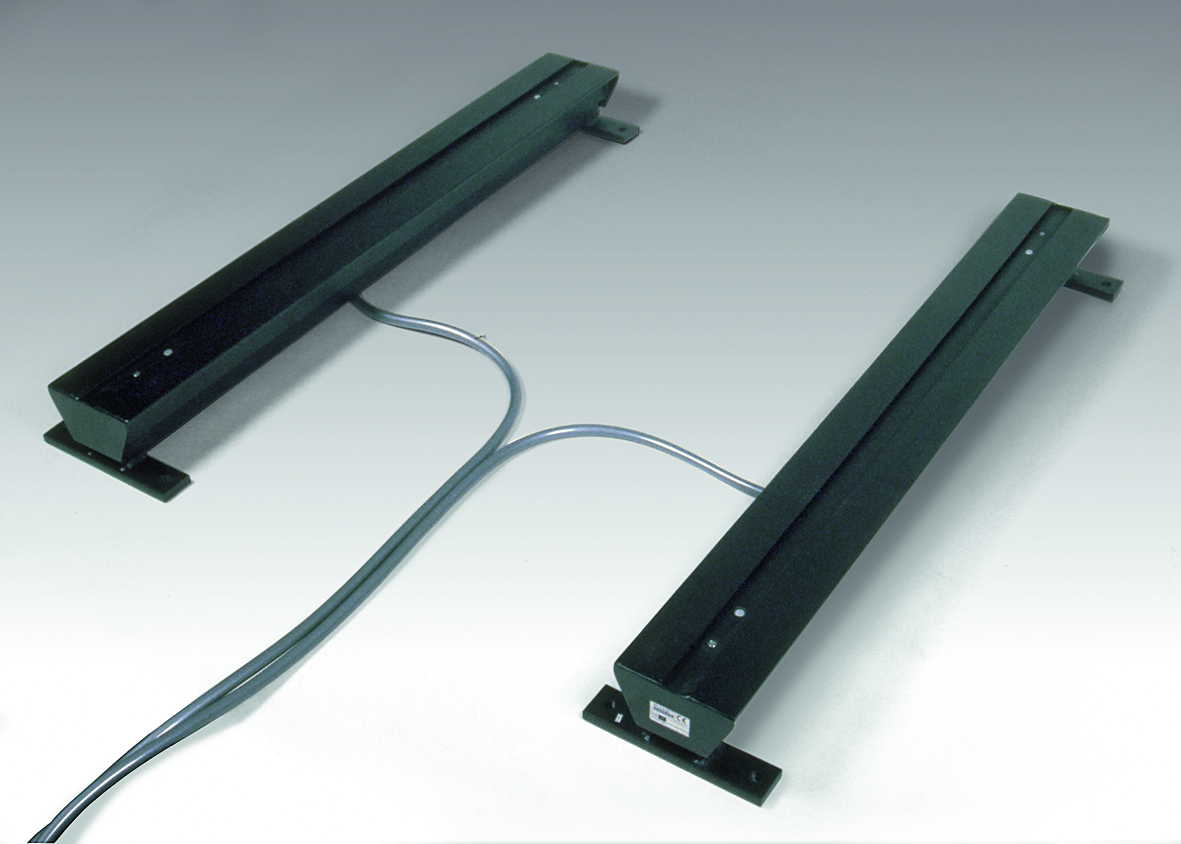

A pair of weigh beams consists of two rails. Each rail is equipped with one or two OIML approved load cells. The weigh beams operate like two separate platform scales connected to each other. This makes the beams suitable in particular for goods with large dimensions. The beams can be flexibly positioned and offer a simple solution for weighing rigid structures (e.g. feed hoppers, belt conveyors, roller conveyors, containers, crates, etc.).

The mechanical part is produced in coated carbon or stainless steel. To protect the beams from impacts, they are fitted with internal mechanical end stops. The cables from each weigh beam are connected to the terminal box supplied (protection class IP67). From the terminal box a 5-metre long cable goes to the electronic unit. The electronic supplies power to the load cells and standardise the weighing signal. The exact total weight of the load on the weigh beams is indicated in the display and/or is transmitted via an interface (e.g. Ethernet, Profibus, Profinet, Modbus or analogue output). Depending on the application software, the weighing system can be used for counting, check weighing or batching operation.

The weigh beams are also available for use in ATEX Zone 1/2/21 and 22.

On request, an ATEX declaration of conformity can be produced for the entire system.

Standard dimensions of the weigh beams

Dimensions L x W x H (mm): 400x80x105

Measuring range (kg): 15

Resolution (g): 2

Resolution calibrated scale (g): 5

Dimensions L x W x H (mm): 400x80x105

Measuring range (kg): 30

Resolution (g): 5

Resolution calibrated scale (g): 10

Dimensions L x W x H (mm): 400x80x105

Measuring range (kg): 60

Resolution (g): 10

Resolution calibrated scale (g): 20

Dimensions L x W x H (mm): 400x80x105

Measuring range (kg): 150

Resolution (g): 20

Resolution calibrated scale (g): 50

Dimensions L x W x H (mm): 600x105x130

Measuring range (kg): 60

Resolution (g): 10

Resolution calibrated scale (g): 20

Dimensions L x W x H (mm): 600x105x130

Measuring range (kg): 150

Resolution (g): 20

Resolution calibrated scale (g): 50

Dimensions L x W x H (mm): 600x105x130

Measuring range (kg): 300

Resolution (g): 50

Resolution calibrated scale (g): 100

Dimensions L x W x H (mm): 800x135x130

Measuring range (kg): 150

Resolution (g): 20

Resolution calibrated scale (g): 50

Dimensions L x W x H (mm): 800x135x130

Measuring range (kg): 300

Resolution (g): 50

Resolution calibrated scale (g): 100

Dimensions L x W x H (mm): 800x135x130

Measuring range (kg): 600

Resolution (g): 100

Resolution calibrated scale (g): 200

Dimensions L x W x H (mm): 1200x150x120

Measuring range (kg): 600

Resolution (g): 100

Resolution calibrated scale (g): 200

Dimensions L x W x H (mm): 1200x150x120

Measuring range (kg): 1,500

Resolution (g): 200

Resolution calibrated scale (g): 500

Dimensions L x W x H (mm): 1200x150x120

Measuring range (kg): 3,000

Resolution (g): 500

Resolution calibrated scale (g): 1,000

Dimensions L x W x H (mm): 1200x150x120

Measuring range (kg): 6,000

Resolution (g): 1,000

Resolution calibrated scale (g): 2,000

Electronic evaluation unit

Display:

Backlighted or Illuminated display

Supply:

110 – 250 VAC, 50 – 60 Hz, 12 – 30 VDC or battery driven

Input:

Full Bridge Strain Gauge Sensors, optional further outputs (e.g. taring)

Output:

Optionally 4 – 20 mA /

RS 232 / 485 / Profibus / Modbus / Wi-Fi /

RF / Bluetooth / USB/

Batching contact / etc.

Enclosure:

Stainless steel or ABS plastic with or without printer

Type of protection:

Up to IP68 (depending on model)

Type of mounting:

Wall- or panel mounting

Working temperature Range:

-10°C to +40°C

Functions:

Counting, check weighing, dosing, filling,

Totalization and formula weighing, peak value