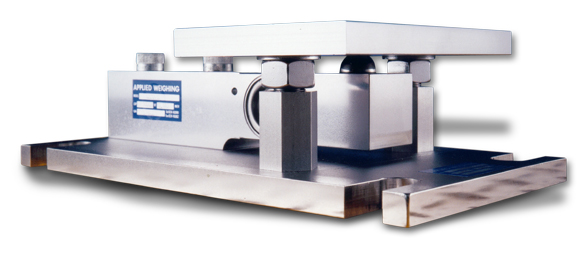

Cleanmount weighing assembly

Simple, safe and sturdy

250 kg up to 10,000 kg

We help you optimise the concept of weighing your products.

Place your request for a quotation now and we will be pleased to give you individual advice on your „Cleanmount“ application.

Immediate advice: +49 (0) 29 61 – 96 56 86

TechGenion

Mars

Pepsico

The added value to you

Safe

Integral lift off and overload protection

Durable

3-year warranty

Explosion protection

ATEX approval for Zones 1/21 and 2/22

Compact

Very low total height

Cost-effective

Economically-priced stainless steel module, easy to clean

Approved for selling?

On request C3 in accordance with OIML

Why is the Cleanmount assembly the right choice for my plant?

With the benefit of our many years of experience we help you to select the right weighing system for your application.

Place your request for an offer now and we will be pleased to help you:

+49 (0) 29 61 – 96 56 86

You are probably familiar with the following situation:

You require an operationally reliable weighing system for a vessel, a mixer or a tank.

The environment is corrosive, damp or in a hygienic area. The weighing system should be easy to clean and offer little space for deposits.

The basic prerequisite is that it should be highly accurate and offer long-term stability.

The ideal solution:

The compact Cleanmount weighing assembly is suitable for vessels of between 500 and 40,000 kg.

It is manufactured entirely in stainless steel and is easy to clean. Dust, humidity and corrosion pose no problems for the Cleanmount assembly.

The vessel can be bolted in place via the Cleanmount assembly (forces to be approved by a mechanical engineer).

Upon request, we will gladly send you a series of information about our products, starting with the access to our data sheets.

How does the Cleanmount module work?

The Cleanmount weighing assembly guarantees safe and precise weighing under difficult environmental conditions.

It is ideal for tank weighing and dosing vessels in the chemical and pharmaceutical industries.

The module is easy to clean, because all the components are manufactured in stainless steel.

The Cleanmount assembly is able to secure the container in all axes. (forces to be approved by a mechanical engineer).

Where required, the load cell can be removed or unloaded prior to mounting.

Technical data

Measurement ranges:

250 kg up to 2,500 kg,

5,000 up to 7,500 kg,

10,000 kg

Total height:

75 – 78 mm,

122 – 127 mm,

135 – 140 mm

Supply:

5-12 VDC, max. 15 V

Output signal:

2 mV/V

Linearity:

within 0.03% max.

Hysteresis:

within 0.02%

Reproducibility:

within 0.02%

Overload protection:

150% of the nominal load

Output resistance:

350 Ohm

Working temperature range:

-35°C to +80°C

Compensated Range:

-10°C to +45°C

Insulation resistance:

> 2000 MOhm

Ex approval [optional]:

ATEX Zone 1/21, 2/22 (also without safety barriers)

British Sugar

Unilever

Frequently asked questions

What is the difference between a weighing assembly and a load cell?

A load cell is the actual element, which measures the force. Standard load cells consist of a metallic body, which is deformed in a defined manner by the force applied.

The deformation is usually measured by metal DMS affixed to the cell and converted into a voltage signal. For small to medium forces bending or shear beams are usually used.

For larger forces as a rule cylindrical bodies or double-ended shear beams are used. When the load cell is loaded with a defined force, it emits a signal, which is proportional to the force (mV/V).

The weighing assembly´s function is to introduce the force into the load cell in the required direction. In the case of containers, the assembly´s function is to secure the container to the load cell and to prevent tilting.

In this way, the accuracy of the load cell should not be impaired, or should be only very slightly impaired. Some weighing modules have additional integral transport, installation and overload protection.

Irrespective of the accuracy of the load cell, the assembly is of primordial importance for the system accuracy of the weighing process.

On how many load cells may a silo, vessel or container be placed?

In order to obtain optimum accuracy, all support points should be weighed. There is no real limit to the number of load cells, apart from cost. Since the load should be distributed as evenly as possible, 3 or 4 supports are easier to balance than 12. Because of the parallel switching in analogue load cells, care must be taken that the measurement amplifier can supply the required number.

What is an anti-lift-off device?

An anti-lift-off device on silos and containers is used, for example, if wind loads or seismic loads have to be taken into account and there is a risk that the silo or the container may tilt over. In the case of wind, for example, in particular when the filling level is low, in relation to the weight of the silo the wind-exposed area is large, and it is then that the risk of tilting is greatest. There are weighing modules with integral anti-lift-off devices and others with separate anti-lift-off devices.

Integral anti-lift-off device:

The anti-lift-off device prevents the silo or container from tilting. The Safemount and Baby-Safemount weighing assemblies, which are used for silo weighing, have integral anti-lift-off devices. The top and bottom mounting plates in the assembly are connected to the load cell by bolt connections. In this way, the assembly compensates a certain expansion (e.g. caused by different thermal coefficients between steel and foundation materials) of the overall structure and also limits the distance that can occur in the case of a lifting silo.

Additional anti-lift-off device

An additional anti-derail device is frequently used for load cells which do not have integral anti-lift-off devices. In this system, the anti-lift-off device can be attached to the load cell itself or directly to the silo or container. When statically required for the Safemount weighing assembly up to 40 t, additional anti-lift-off device, which are attached directly to the weighing assembly, are available. In this version, two vertical threaded rods are screwed into the bottom mounting plate. Each of these protrudes through a drilled hole in the top mounting plate without touching the plate. The maximum withdrawal distance is limited by a nut above the top plate at 2 – 3 mm and additionally secured by a lock nut.

What are stay rods?

Stay rods are needed for cylindrical load cells with what are known as self-aligning bearings, in order to prevent rotation of the container. The stay rods limit the horizontal movement of the container; however, they usually allow frictionless vertical movement.

What effects do wind loads have on accuracy of weighing?

Lateral forces, such as wind forces, largely balance out due to the parallel switching of the load cells. When one side of the silo is relieved of load by the wind, the load on the other side increases.

The sum of the forces therefore remains the same. Wind loads are identifiable only in case of strong gusts of wind, when the mean value creation (damping filter) of the measurement amplifier has been greatly reduced.

How far from the load cells may the measurement amplifier be located?

All „modern“ measurement amplifiers have what is known as a „sense“ input. In standard load cells only four conductors are required for measuring. These are two conductors for the supply (5 – 15V) and two conductors for the measurement signal.

If the measurement amplifier is located at a distance of more than 10 m, we recommend two additional conductors for the „sense“ line. The measurement amplifier „measures“ through the sense line how much voltage is dropped in routing and mathematically compensates for the voltage drop.

Where there is sufficient wire cross-section and separate transfer of the shielded connecting cable, distances of up to 200 m are feasible. For greater distances, we recommend the use of an amplifier on site at the silo or a bus connection via the Intelligent Junction Box.