Intelligent Junction Box

The new weight-monitoring generation

We work with you to optimise commissioning and monitoring of your load cells

Place your request for a quotation now and we will be pleased to give you individual advice on using the „Intelligent Junction Box“.

Immediate advice: +49 (0) 29 61 – 96 56 86

The added value to you

Uncomplicated

Simple monitoring of each individual load cells

Maintenance-friendly

Sturdy design – suitable for industrial use

Smart

Relay output signals „all functions OK“

Safe

CAN bus interface for safe transmission of the signal to the measurement amplifier

Intelligent

No external power supply required, long transmission length via CAN bus

Independent

Detects overload, underload and imbalanced load of the load cells

Clear

Bright, high-contrast OLED display

Why is the „Intelligent Junction Box“ the right choice for my plant?

With the benefit of our many years of experience we help you to select the optimum electronic evaluation unit for your application.

Place your request for an offer now and we will be pleased to help you:

+49 (0) 29 61 – 96 56 86

You are probably familiar with the following situation:

The container is mounted on the load cells and the plant can be commissioned.

Now the correct workload for each of the load cells should be checked. To do this, you need a high-quality multi-meter for measuring the individual signals.

The signal line for each load cell is disconnected, the signal is measured and then re-connected and the next load cell is checked.

Where required, the container foot must be shimmed / lined; then you start all over again…

The ideal solution:

With the „intelligent junction box“ you have all the load cell signals in sight at once.

The individual signals (mV/V) appear in parallel on the display and the result of shimming is immediately obvious.

A fault in the wiring, a cable break, as well as underload and overload can be displayed and transmitted to the measurement amplifier. This makes sense both for mounting and for monitoring during operation.

Monitoring of every single aggregate in the field level is part of the philosophy behind the Industry 4.0 initiative. The intelligent junction box puts these ideas into practice.

Upon request, we will gladly send you a series of information about our products, starting with the access to our data sheets.

How does the Intelligent Junction Box work?

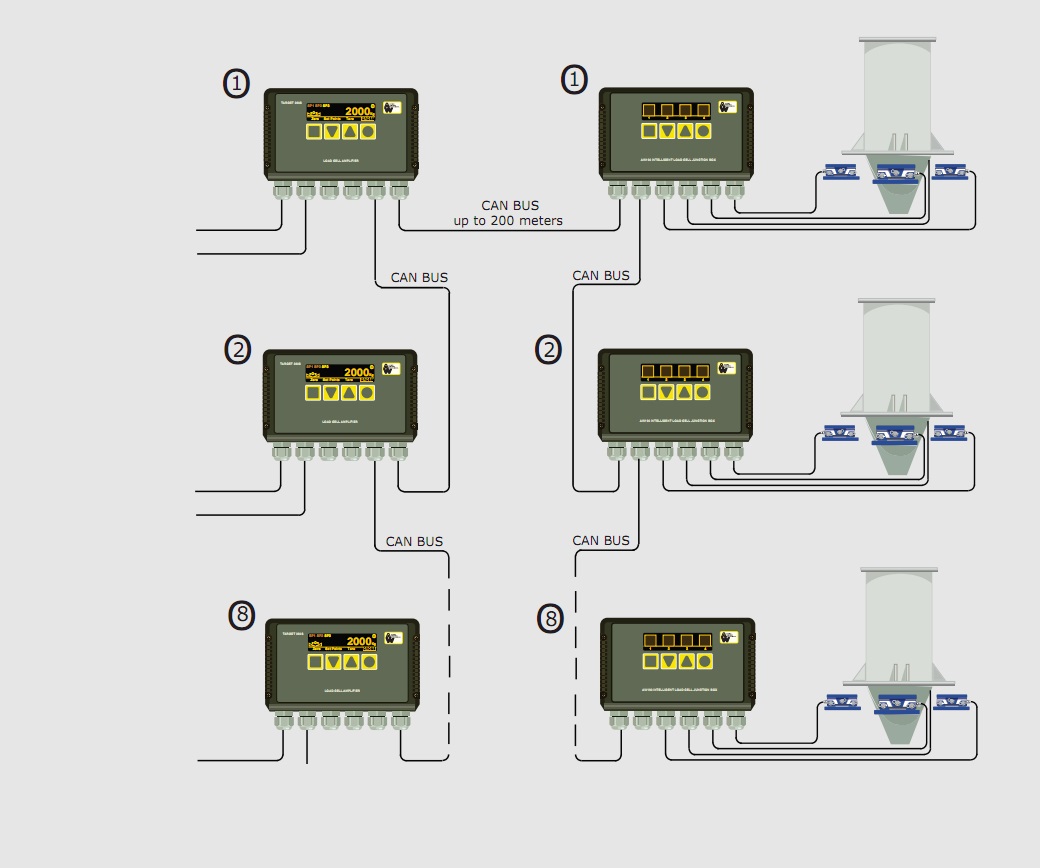

The „Intelligent Junction Box“ can monitor up to four load cells.

For more than four load cells it is possible to link up to eight junction boxes together through the CAN bus.

The individual signals are added up in the electronic evaluation unit.

The malfunction messages are displayed and acknowledged on the „Intelligent Junction Box“ and on the downstream evaluation device. Each fault message (e.g. a cable break) can be suppressed or displayed as a warning or alarm, which must be acknowledged.

Technical data

Housing:

IP65 plastic for rail or wall mounting,

optionally available in stainless steel

Display:

Bright, high-contrast OLED display,

256×64 pixel

Dimensions:

174 x 120 x 37 mm,

Mounting 162 x 88 x 4.5 mm

Weight:

0.65 kg

Power supply:

5 – 10 VDC / 60 mA by means of supply to the load cell electronics,

alternatively 24 VDC externally

Inputs and outputs:

4 full bridge strain gauges, CAN bus,

Load cell sum signal

Relay contact to fault message