MIC Flow Meter

The reliable flow measurement system

We work with you to optimise the monitoring and recording of pneumatic conveyed solids

Place your request for a quotation now and we will be pleased to give you individual advice on your specific application.

Immediate advice: +49 (0) 29 61 – 96 56 86

The added value to you

Safe

High degree of operational reliability

Maintenance-free

Once installed, no maintenance necessary

Options available

ATEX versions for the Ex areas Zone 20, 21 and 22 available

Simple

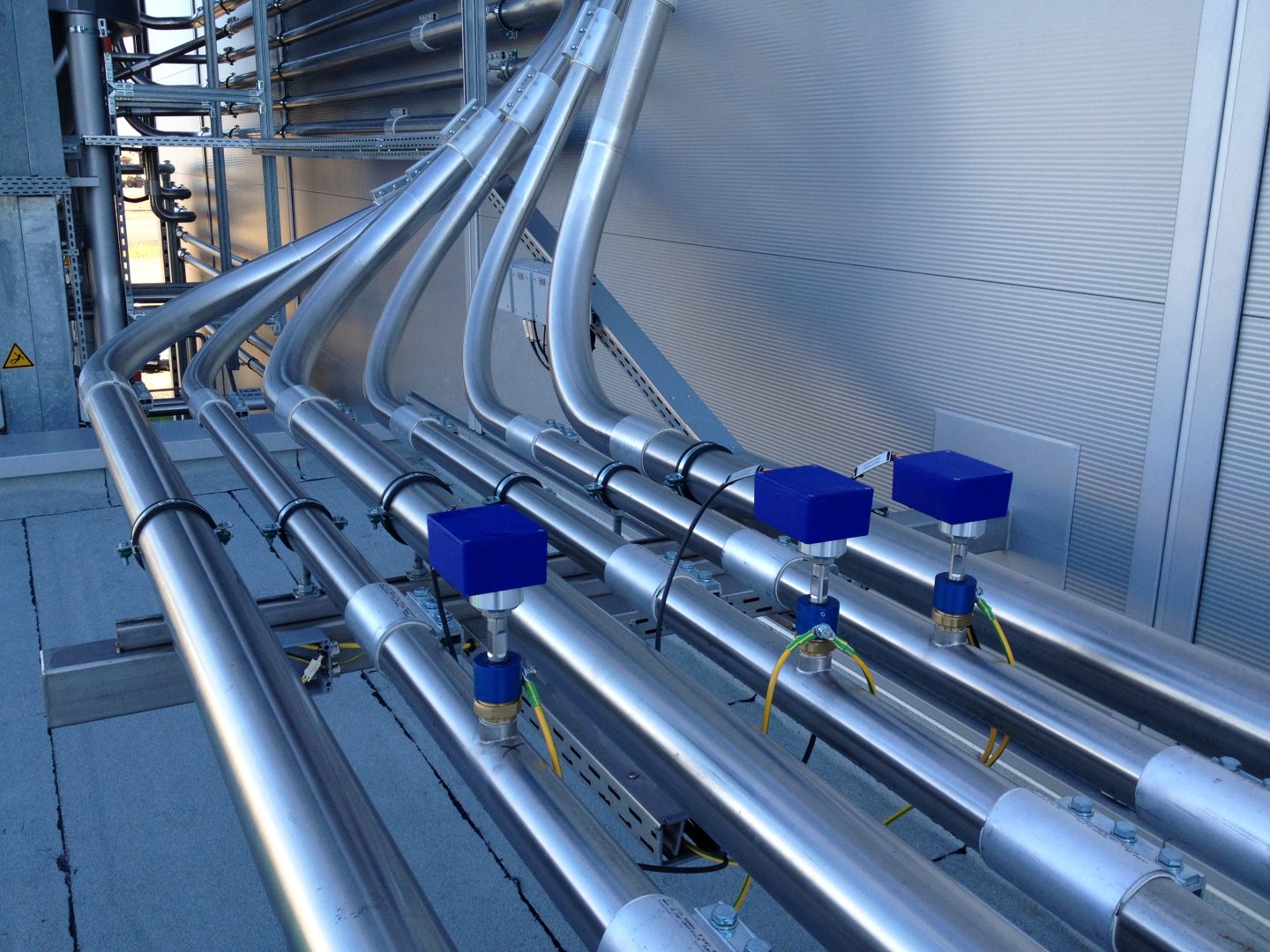

Very easy to install in existing conveying systems (without adding extra height)

Non-contact

Measures flush with wall, therefore wear-free

Intelligent

Records only „moving particles“

Comprehensive

Up to 140°C and 15 bar

Why is the MIC Flow Meter the right choice for my plant?

With the benefit of our many years of experience we help you to select the right measurement system to monitor your solid flow.

Place your request for an offer now and we will be pleased to help you:

+49 (0) 29 61 – 96 56 86

You are probably familiar with the following situation:

You need a reliable flow meter for process control in a pneumatic conveying system or in a “free fall application”

The device should monitor the flow and should be as maintenance-free as possible. It should be simple to mount, so that no modifications need to be made to the plant.

The ideal solution:

The MIC sensor offers a cost-effective solution for monitoring the flow of powder and grain material in a pneumatic conveying system.

The sensor is mounted flush with the wall and is therefore maintenance- and wear-free. Measurement is based on analysing the reflection of the microwave radiation into the product fed through the pipe.

Upon request, we will gladly send you a series of information about our products, starting with the access to our data sheets.

How does the MIC Flow Meter operate?

The MIC microwave measuring system consists of a sensor head with integrated electronic and a stainless-steel wave guide.

At first a hole must be drilled into the pipe or chute the sensor should be installed. Then a threaded socket is welded onto the sensor position.

The sensor is installed flush with the wall – therefore measurement is wear-free and maintenance-free.

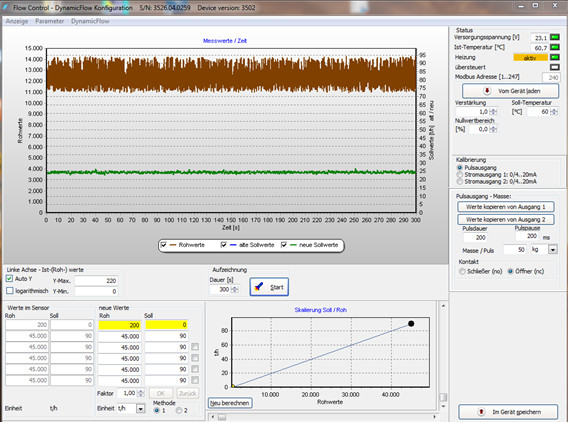

On its front edge the sensor emits a measurement frequency of 24 GHz. The solid particles flowing through reflect an impulse spectrum, from which a patented algorithm determines flow stream and velocity.

The electronic, integrated into the sensors head, transmits the flow rate value in kg/h (t/h), the speed in m/s, and the absolute flow volume in kg or t to the control system or monitor.

When calibrating the sensor, the software supplied in the scope of delivery can be used to calibrate the system and to visualise the signal path.

The system is largely independent of pressure and temperature and thus offers a reliable base for monitoring, measuring and regulating powder and granular in pneumatic conveying process or in free-fall lines and transfer chutes.

Where the pipe diameter is more than 300 mm, a second sensor should be mounted to increase the accuracy of the measurement. The sensors are averaged to get a better result, even with uneven distribution of the solid particles.

Materials

Sensor:

Stainless steel V4A with ceramic coating

Housing:

Aluminium

Type of protection:

IP66

Connection pieces:

1“ NPT

Optional:

ATEX approval for Zone 20 within the pipe, Zone 21/22 exterior to the pipe

Technical data

Supply:

24 VDC

Power consumption:

400 mA

Measurement frequency:

K band (24, 125 GHz)

Output:

2 x 4-20 mA, impulse output or ModBus (Profibus DP optional)

Accuracy:

+/- 2 to 5% (depends on application)

Working temperature range:

-10°C to 70°C / optionally up to 140°C

Pipe:

DN50 to DN300, and rectangular channels; larger diameter with several sensors

Dimensions:

Sensor housing 115x90x82 mm, wave guide 150×19 mm or 250×19 mm

Frequently asked questions

For which products can the flow be measured?

The MIC microwave system has been developed for the continuous recording of quantity for pneumatically transported (fly conveyance not dense phase conveying) and free falling bulk goods. Therefore, a very wide spectrum of products can be measured.

What measuring ranges can be covered?

The MIC sensor is suitable for mass flows from a few kg/h up to several 100 t/h. The throughput possible also is directly dependent on the diameter and cross-sectional surface of the pipe.

How can I tell whether my product can be measured with the MIC sensor?

The measuring system is largely independent of pressure and temperature. Particulate products in fly conveyance (pneumatic conveyance) or in free fall can be measured with the system. The prerequisite for high accuracy in measurement is that the particles of the bulk goods to be measured are distributed as evenly as possible in the pipe. Thick streams or clumps reduce the accuracy of measurement. Ideally an inlet and outlet pipe amounts to a number of times the diameter of the pipe. We will be happy to advise you on determining the optimum position for the MIC sensor.

How high is the level of accuracy of the system?

Typical measuring accuracy in pneumatic conveying systems lies between 2 – 5% and 5 -10% in freefall applications. The prerequisite for high accuracy in measurement is that the particles of the bulk goods to be measured are distributed as evenly as possible in the pipe.

For which applications is the MIC sensor used?

Balancing material flows, process control, flow monitoring (flow/no-flow variations), continuous dosing and regulation of additives

What are the limitations of the system?

Since the microwave signal from the sensor transmits the particle size and amount, but not the density, when there is a fundamental change of product or a relatively major modification in the bulk goods characteristics (e.g. humidity), the system has to be re-calibrated.

What are the requirements for maintenance?

The microwave sensor records the throughput of bulk goods without coming into contact with the material and is therefore maintenance-free. The stainless-steel measurement socket from V4A is additionally clad in a ceramic protective coating. The high-temperature model can be used at up to 200°C.

In which industries is the MIC sensor used?

The measuring principle is suitable for an extremely wide variety of products and therefore for nearly all sectors.

What interfaces are possible and what data is transmitted?

Unlike in earlier models, the evaluation unit for the MIC Smart is located in the head of the sensor. This has two 4-20 mA analogue outputs (for example to transmit the flow volume on channel 1 and the product speed in the pipe on channel 2), plus an impulse output. The sensor has an RS485 interface, which can be requested by Modbus protocol.

Are modifications in my plant necessary, in order to install the system?

The installation of a large number of flow measurement devices necessitates the renovation of the existing plant. However, the microwave sensor is easy to include in existing plant. To install the sensor a 24-mm hole has to be bored in the feed pipe. The half socket supplied is welded centrally around the hole. A ball valve and clamp are screwed on. The ball valve makes it possible to operate the pipe without the sensor. The sensor is inserted into the clamp. Where required, the insertion depth can be defined by circlips. This completes the mechanical part of installation.

The electricity supply is connected directly to the head of the sensor, since this already contains the electronic encoder, including the interfaces. For this purpose, we supply a ready-made cable.

In the ATEX version of the MIC Smart sensor the cable length is adjusted to the application, so that the securely connected sensor cable can be led out of the hazardous area and into the safe zone.